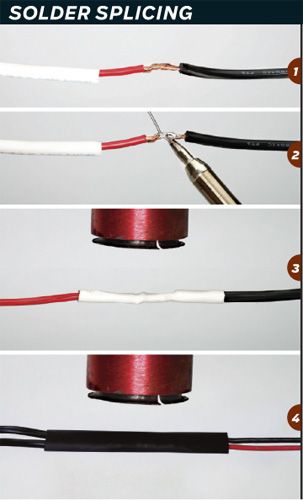

How To Solder Trailer Wires Together

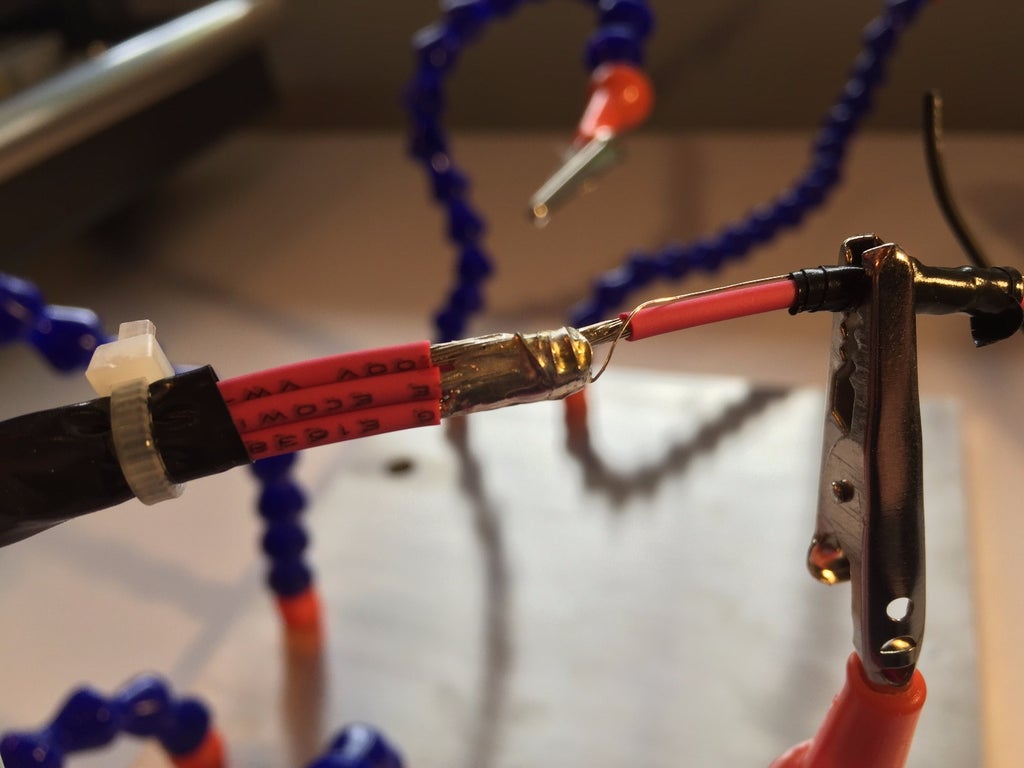

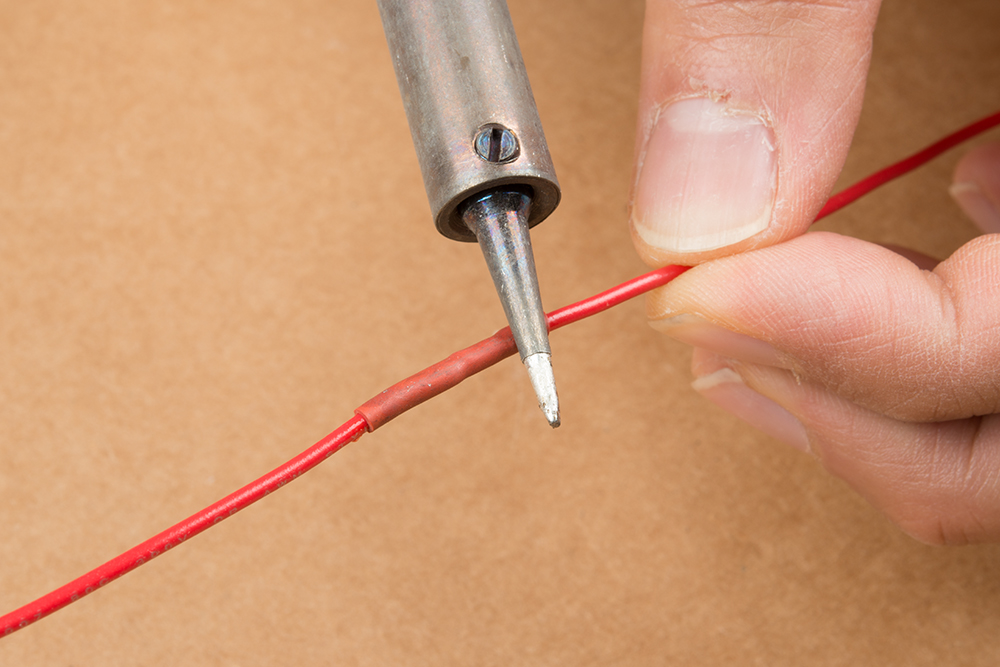

Preload the Soldering Iron Tip with Solder Wire.

How to solder trailer wires together. Wiring a seven-blade trailer connector. Apply Solder Flux to the Wire Joint. Be sure to place the shrink-wrap tubing on prior to connecting the wires if that is.

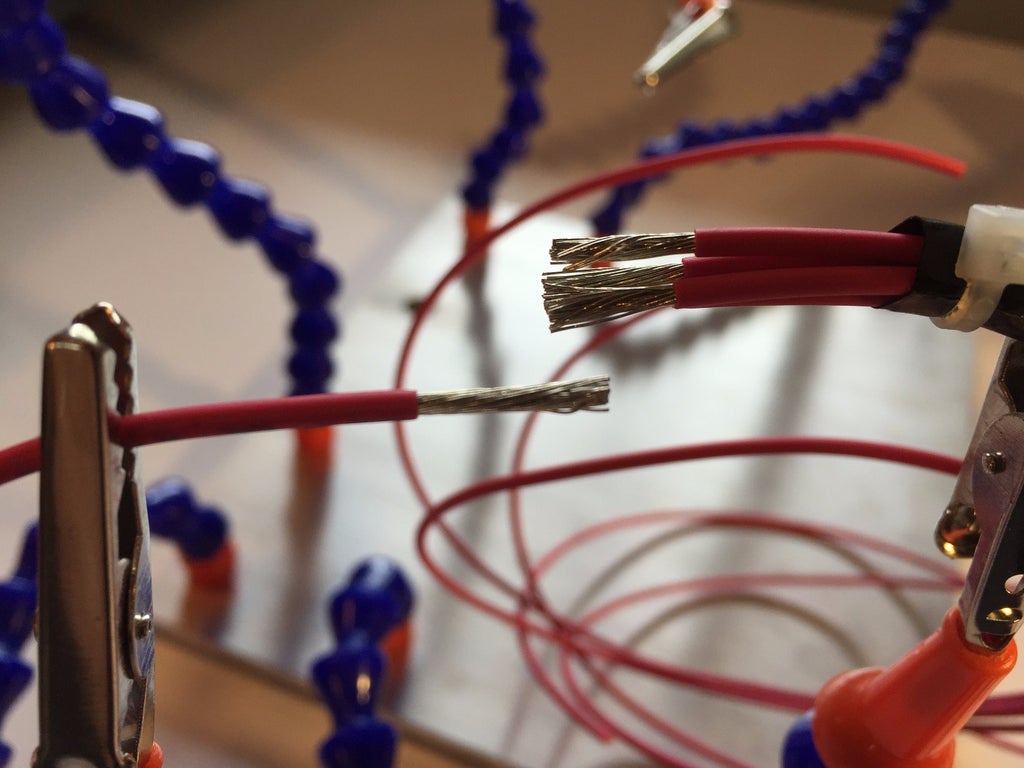

How To Solder Wires Like A Pro. The first two splices require that about a half-inch of the insulation be removed from both of the wire ends. Both of these will work to solder wires together and lead free solder is more environmentally responsible but let free solder just doesnt work as well Lead solder is easier to work with because it soaks into the wire strands better and has a lower melting point so thats what I primarily use and I prefer this 6040 rosin core solder which gives me the best results and a quick tip just in.

If you are replacing an existing wire from your seven-blade trailer connector remove the cover of the junction box. This tool worked the best for me in the automotive application and make it a breeze get that tuff to reach wires repaired soldered and sealed properly. Touch the tip of the soldering iron to the wires and keep it there.

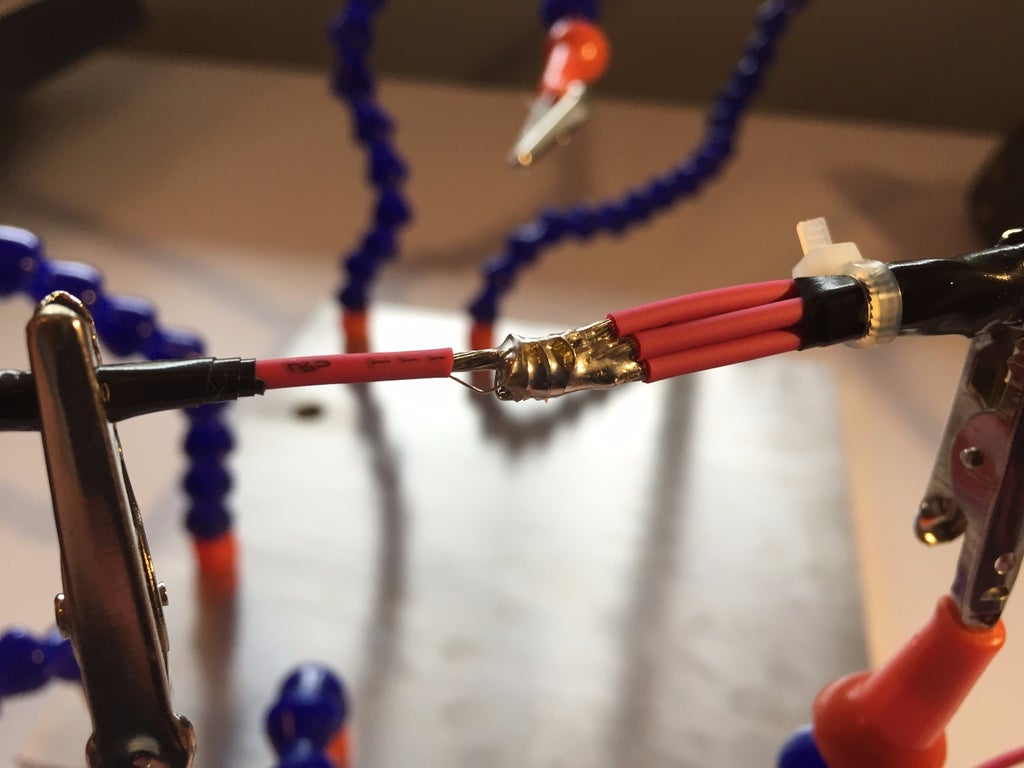

Insert Heat Shrink Tubing through the Wire to Cover the Solder Joint. Also make sure that the flux bubbles but not burn. A few tips and tricks to use when soldering is to first always make sure you do not have a cold solder joint make sure you are using the right solder for the job and always make sure you seal your solder joint from all types of weather.

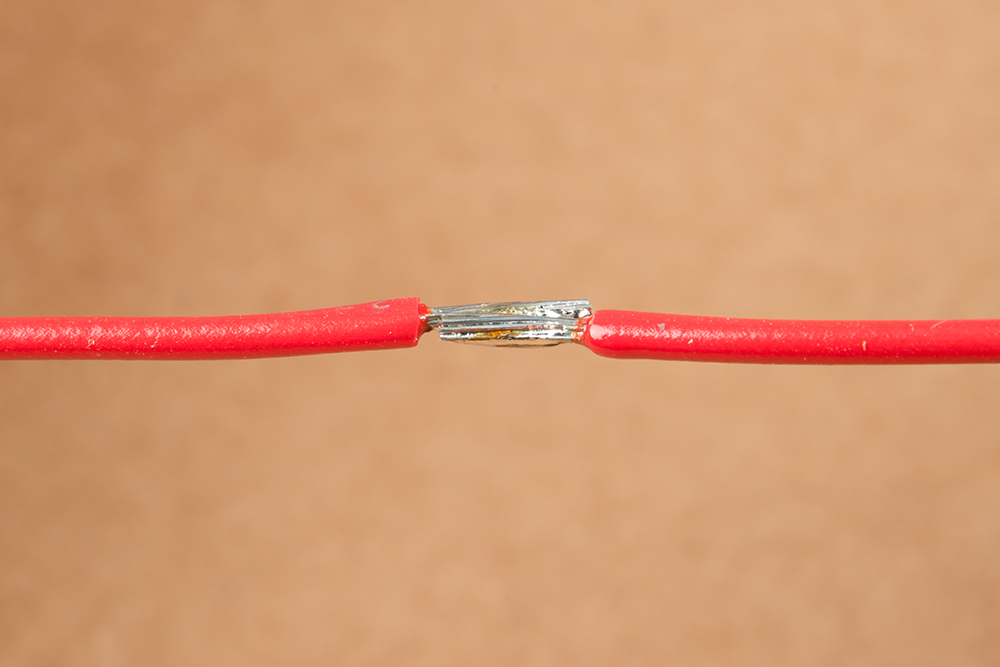

Then apply heat making sure you keep rotating the wires so it doesnt get too hot too fast in one spot. Push one wire all the way through the connector then overlap the bare ends of the wires to be connected do not twist them. Crimping will work well as Cougar suggested but if you really want the splice to be waterproof and permanent solder the wires then put heat-shrink tubing over the splice.

Use heat shrink tubing to protect the soldered connection. Then use a pair of pliers to push the metal tap down into both wires flush with the body of the connector and snap the cover over the tap. Heat the solder enough so that it is melted evenly along the joint being soldered.