How To Properly Solder Small Wires

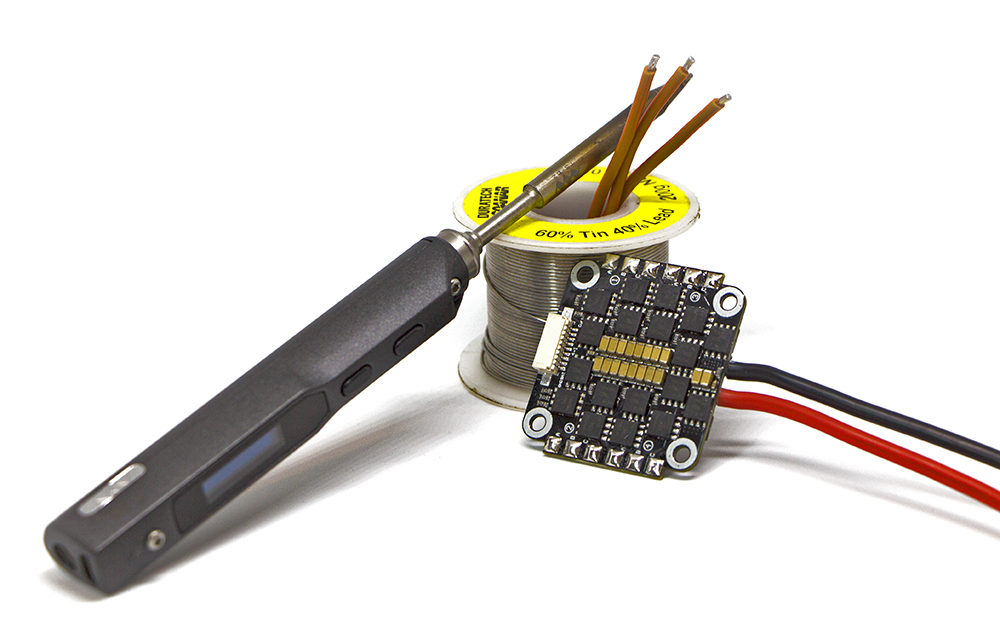

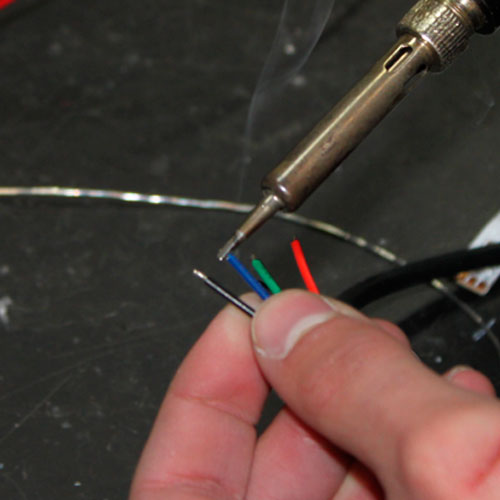

Then connect the soldering iron tip right on the wire.

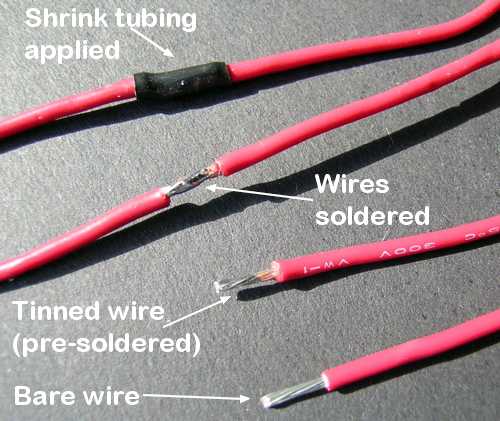

How to properly solder small wires. There are small lies big lies and then there is what is on the screen of your oscilloscope. You need to apply the heat to the metal part on the plug because that takes the longest to heat and melt the solder. You have to use leaded solder though because this will pull the enamel wire right onto the center of the pin or pad.

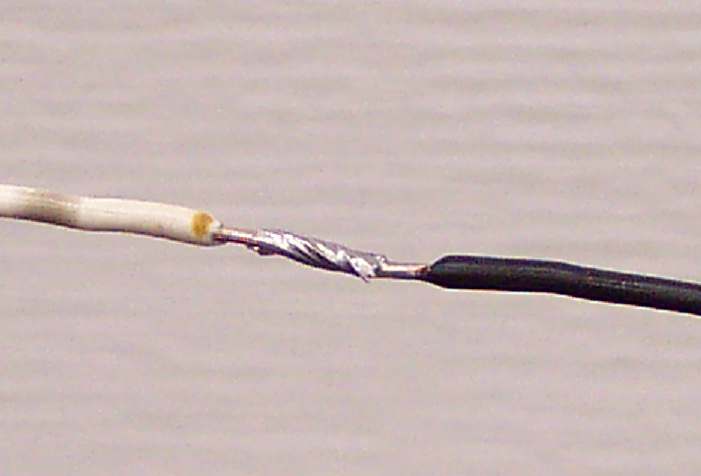

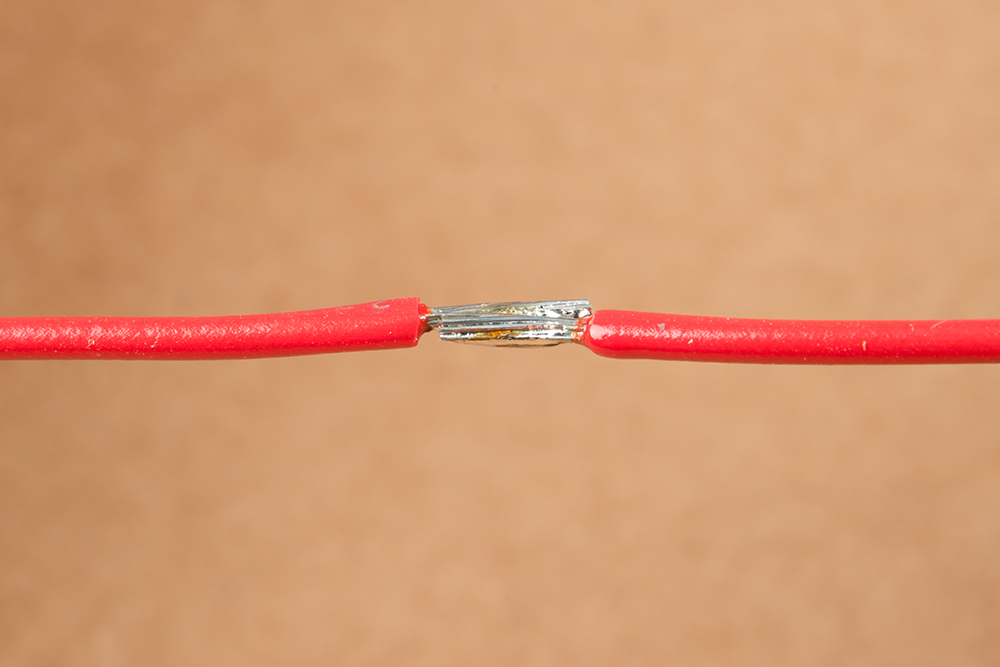

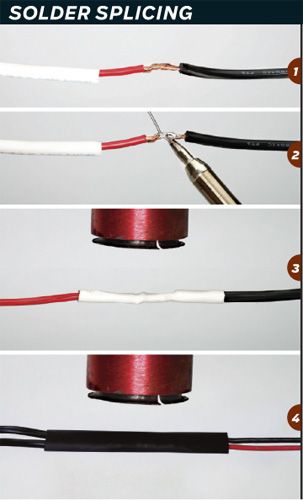

Bring the soldering iron tip close to the twisted wiring. Just seat them where you want them and find a way to hold them in place with clips or by bending the leads outward slightly so they stay put when you turn the circuit board over. Apply Solder Flux to the Wire Joint.

Before touching the soldering tip to the wires tin the tip by melting a small amount of solder on it. This will help conduct heat to the wire. This helps to spread out the heat when the tip touches the wires.

Remove the soldering iron and wait a few seconds to let the soldered connection cool and harden. If you did the cable and the tag at the same time by the time the solder properly melted the wire insulation would have started to. Preload the Soldering Iron Tip with Solder Wire.

Place the tip of the soldering iron to the connection. Solder the Wire Joint. When melting the solder to the wires try not to touch the iron with the solder.

Wrap one or two inches of solder around the tip while the iron is cold. If you screw up let it cool before you start over so you dont melt too much. Then remove your hand and hold the twisted section with a plastic stick.

/close-up-man-hands-soldering-audio-cable-with-xlr-connector-1078041206-472dd1f03b084f2b9ab373c9dff8080e.jpg)