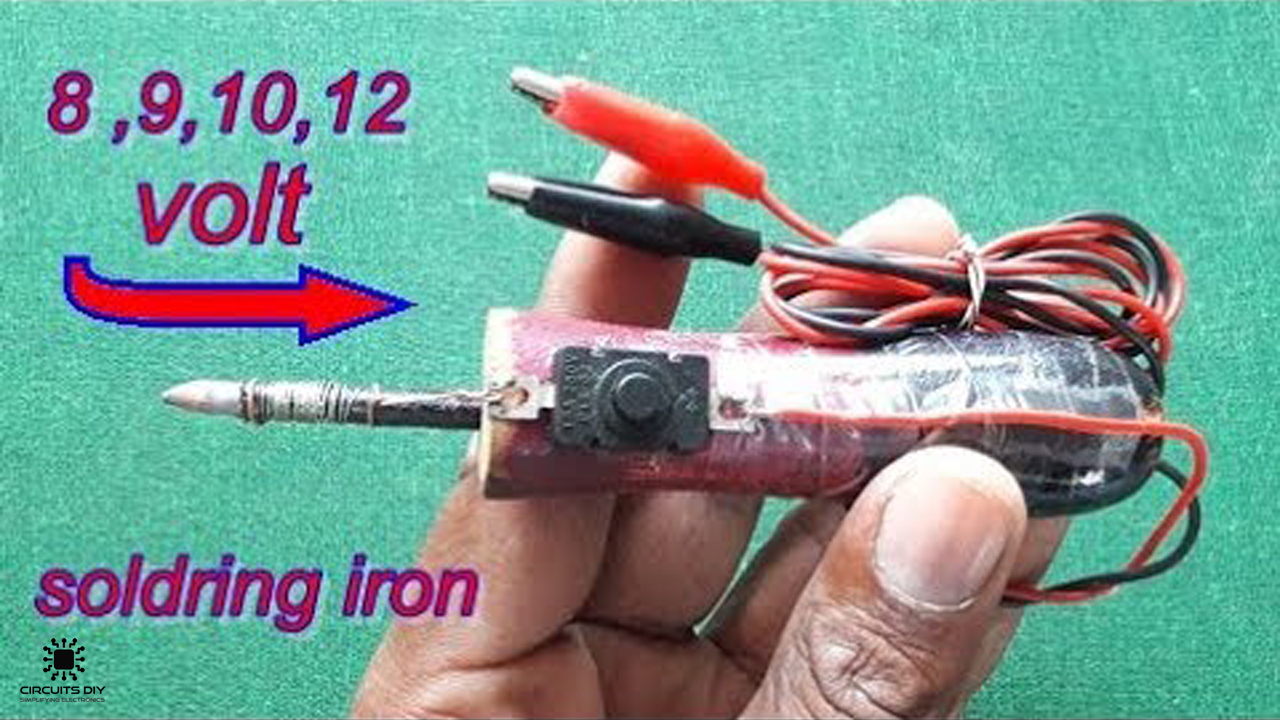

How To Make A Soldering Iron With Household Items

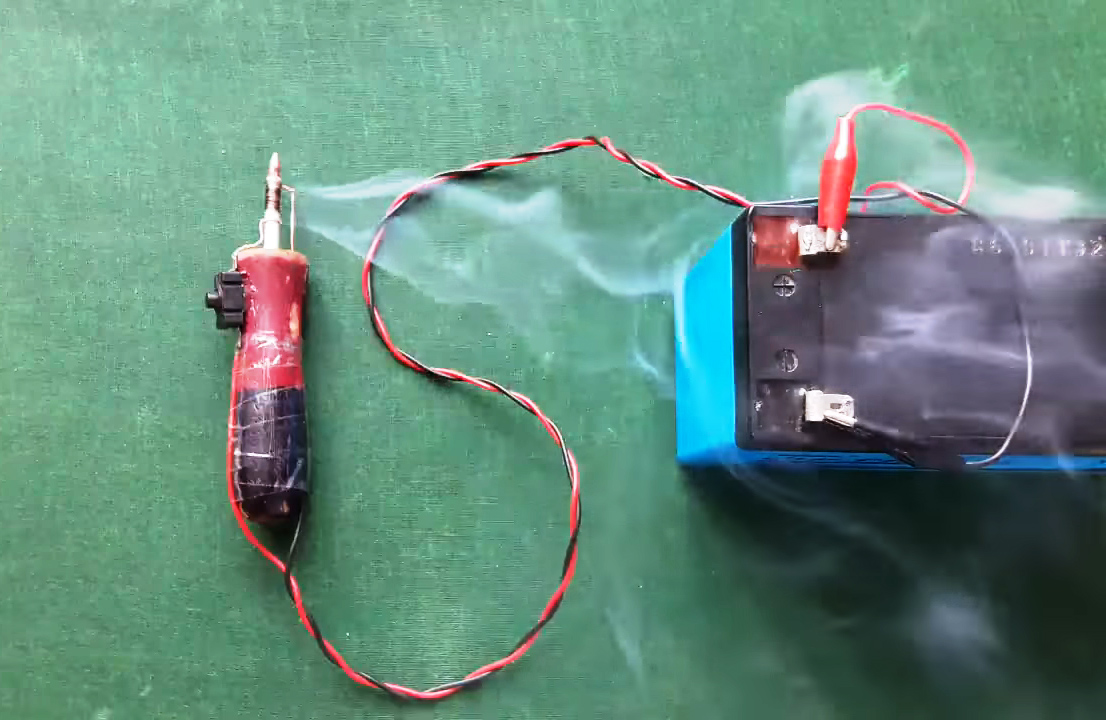

A defective heating element will keep the soldering iron from functioning correctly and should be repaired.

How to make a soldering iron with household items. Posted by 6550 at 417 PM on March 15 2012. This makes the tip transfer heat faster and thereby making the soldering easier and faster. There are two tools I use for desoldering.

I found that without solder it is very difficult to get the solder to suck into the wires. You can make a citric acid-based flux from ordinary household supplies that will prepare an object for soldering. Just heat the solder joint to make the solder fluid then suck it off with the solder sucker.

How to make and use your own solder wick. A simple soldering iron that has a cord that is plugged into the mains is generally referred to as a plain soldering iron. If you have ever had to wait a long time for your soldering iron to heat up the large connectors that you are soldering an 800W RSU might be a handy addition to speed things up.

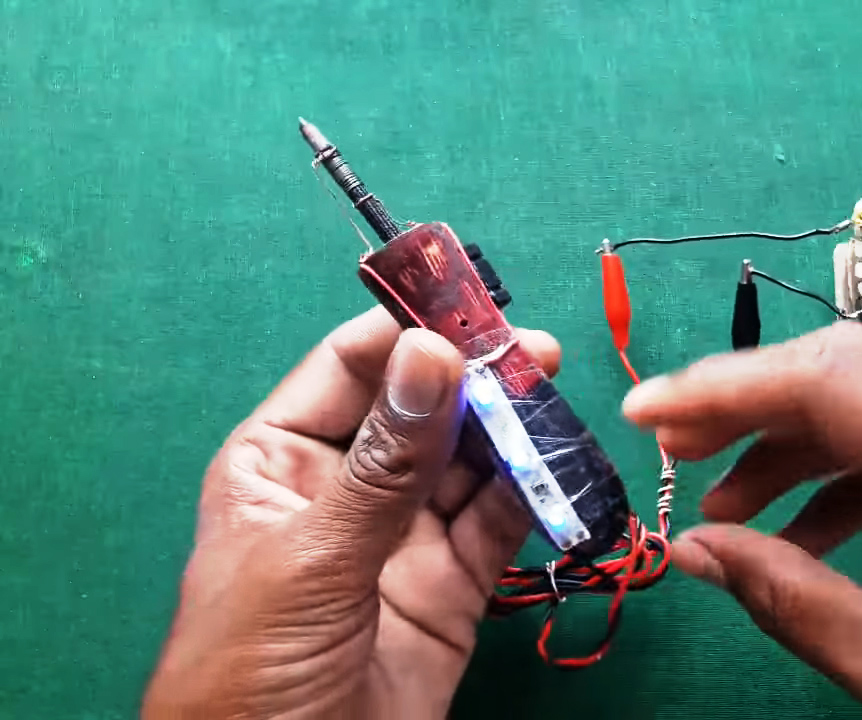

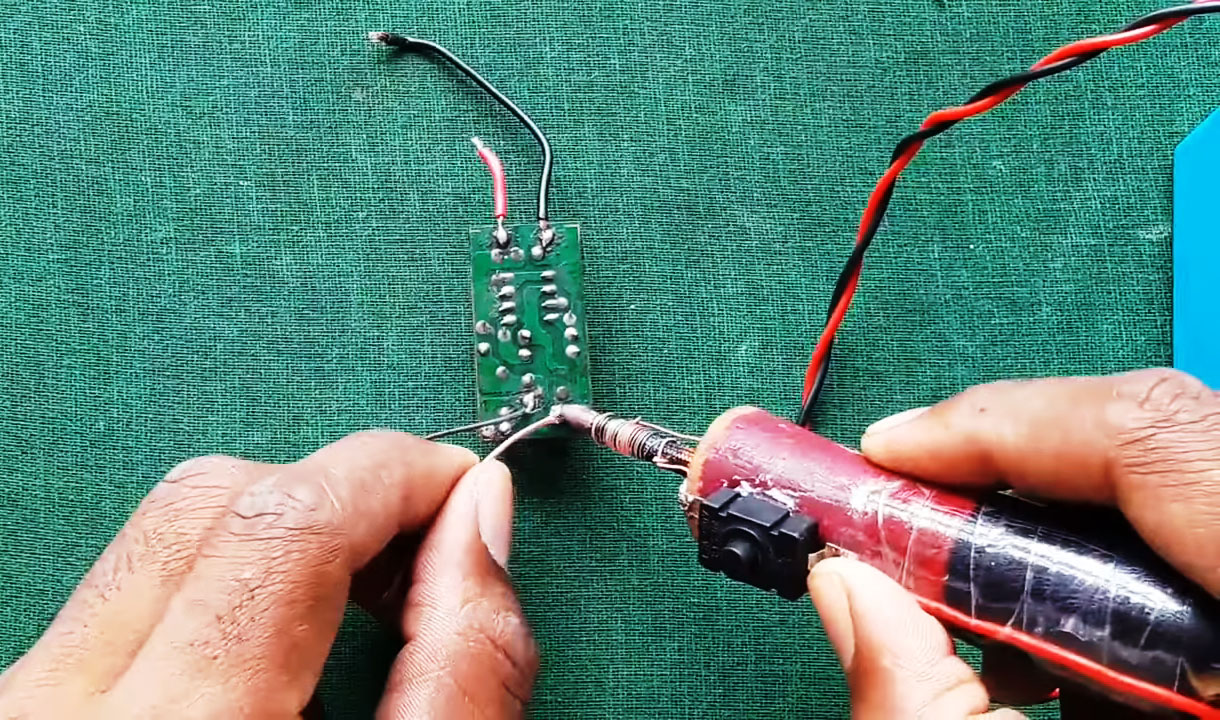

A soldering iron functions by heating up an element that transfers heat to the tip. Step 2 Heat your soldering iron and touch the tip to the top of the braid. You can make something like a simple distortionboostoverdrive using a transistor or two a few resistors and capacitors and a 9V battery for well under 10.

Pull the copper out the side of the slit and cut off the excess insulation. It sucks the solder away from the solder joint. As it melts this solder material is directed to flow into the spaces between and around two components or workpieces.

Once you get it working for the types of jobs you do Id recommend making a wooden box to house the RSU or possibly buying a plastic tool-box. All that was left was to make four solder connections to the flashlight contacts and a 5-A fuse connect the Magnastat components with wire nuts. Step 1 Place a piece of the desoldering braid on top of the jointsolder you want removed.