How To Solder Automotive Wiring

Apply enough solder so that every strand of wire is surrounded by solder.

How to solder automotive wiring. Remove the soldering iron and wait a few seconds to let the soldered. Be sure to remove all of the damaged wire section. It helps to start the heat transfer by dabbing the solder at the point.

Automotive wiring should be soldered and protected properly in order to withstand all types of weather rain snow and salt. Standard automotive primary wire is 18 gauge. Apply a little solder to the tip before applying heat to the twisted wires.

Bend the ends of both tinned wires into a U-shape with needle nose pliers. Hold the two tinned wires on top of each other and touch the soldering iron to both wires. Its the act of using heat via a soldering iron and a fusible metal the solder to create the electrical connection.

This process should melt the solder and coat both wires evenly. Try sourcing some alli solder it may work for your particular wire. I have tried to get the solder to attach to the wire with and without flux but no luck.

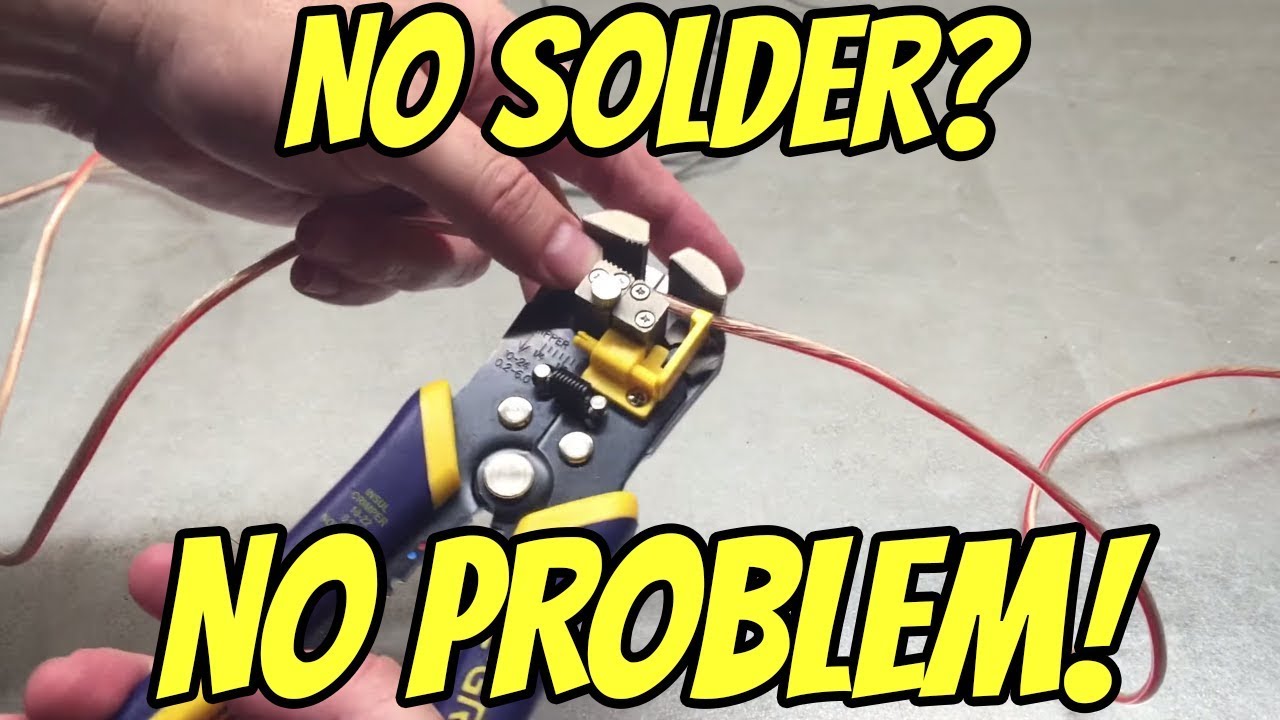

Automotive-grade stranded wire thats the same gage as the old wire. Dead link also not available on the Wayback. This tool worked the best for me in the automotive application and make it a breeze get that tuff to reach wires repaired soldered and sealed properly.

The best tool for the job is a soldering iron such as Master Appliances EconoIron. If your re-wiring your car or truck then this is a MUST Video For YOU. Other wires I just crimp and cover with heat shrink if possible.