How To Prepare Soldering Flux

Step 1- When soldering two pieces it is good to use steel wool or scotch brite to remove oxide layers from the surface.

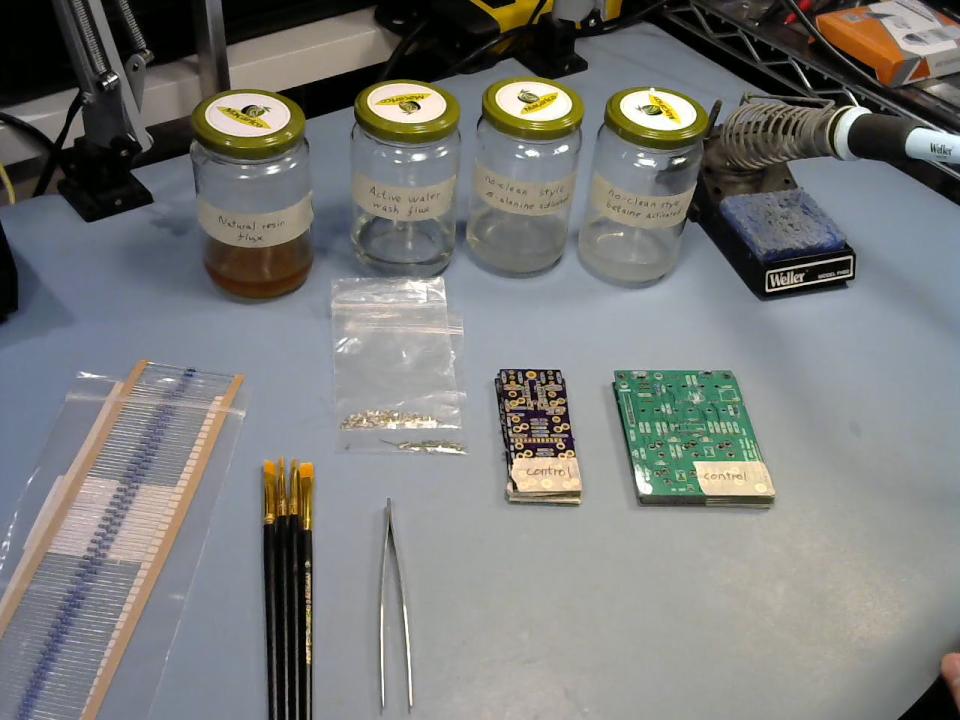

How to prepare soldering flux. Soldering flux is only corrosive once it is heated up and in its liquid form. Well get you started and dont miss the giveaway at the end of the video. Begin by making sure the tip is attached to the iron and screwed tightly in place.

Push the soldering gun onto a side of your wires to melt flux. Flux is also formulated to remove any oxidation from pipe and actually etches pipe surface in preparation for the soldering process to be successful. Maintain proper angle between the two.

Make sure the soldering iron is hot. If there is any debris or dirt it will have to be cleaned off. Got home and realized it doesnt mention rosin anywhere on the package and neither does the online listing.

Place the strainer in the kitchen sink for washing later. 100C on the topside of the board just before soldering. Will create a barrier between the metal and the solderThink of the dirty surface like plastic wrap over your ham sandwich your potential solder join.

Do nothing until all of the juice has strained through. Clean and Prepare Your Materials. The tinning process protects the tip from oxidation reduces wear and enhances heat transfer.

Wipe any excess flux off your fingers or brush before soldering. How to Solder Step By Step. Wipe of the excess flux from the soldered joint with a piece of paper towel.