How To Solder Fine Electrical Wires

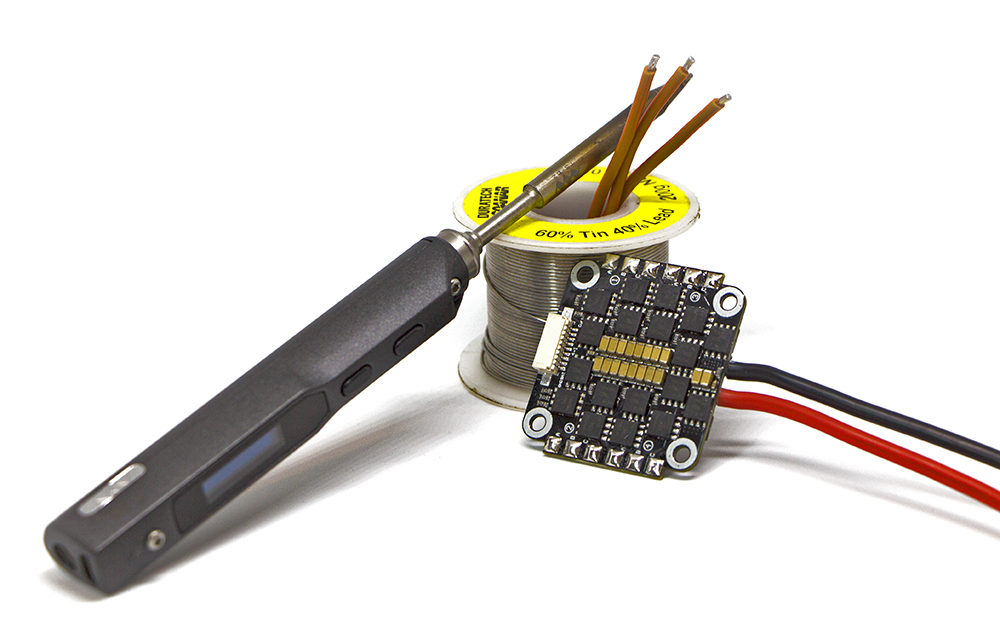

Make sure your soldering iron is fully heated and touch the tip to the end of one of the wires.

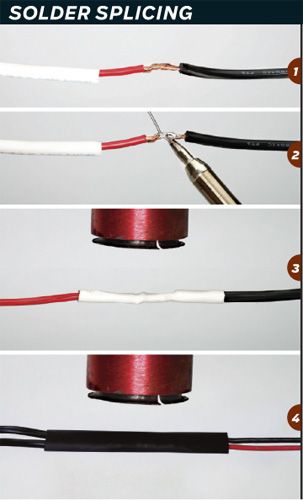

How to solder fine electrical wires. When doing splices clean the wires by scrapingbrushingsanding solder tin the wires to be joined slide clear heat shrink tubing over one wire lay the tinned ends together and touch them with the soldering iron and they will fuse nicely then slide the clear heat shrink tubing over the joint heat shrink one end pack it with petroleum jelly then heat shrink the other end. Tinning the tips of stranded wires holds the fine wires together and makes it easy to connect them to screw terminals or other connectors. Hold it on the wire for 3-4 seconds.

Its the act of using heat via a soldering iron and a fusible metal the solder to create the electrical connection. Keep the iron in place and touch the solder to the wire until its fully coated. How to Solder Two Small Wires - YouTube.

When you are tinning the wires the resin will help the solder flow smoothly. When soldering it is always a good idea to disconnect the wires from the electronics whenever possible as the heat can easily transfer to the electrical components. If you use flux it must be for electronics any other will ruin the wire in a short time as most are acid.

There is one way to twist wires together for soldering- a horizontal twist that yields a continues length of. Please dip the litz wire without removing enamel coating into the soldering jarpot. If the wire is stranded twist the strands together with your fingers.

Begin by removing the insulation from the ends of both wires you are soldering together. The solder jar is made up by approx. If that is enammelled wire as it appears then as others have said the best method of stripping is to heat the ends with a flame to destroy the insulation and scrape off the residue.

The solder should be fed into the cool side away from the heat which allows it to be drawn in smoothly by the heat transfer through the wires. How to Solder Wires Together Best tips and tricks - YouTube. You may select the dipping time as per your litz wire AWG size as below table.