How To Make Solder Tips Last Longer

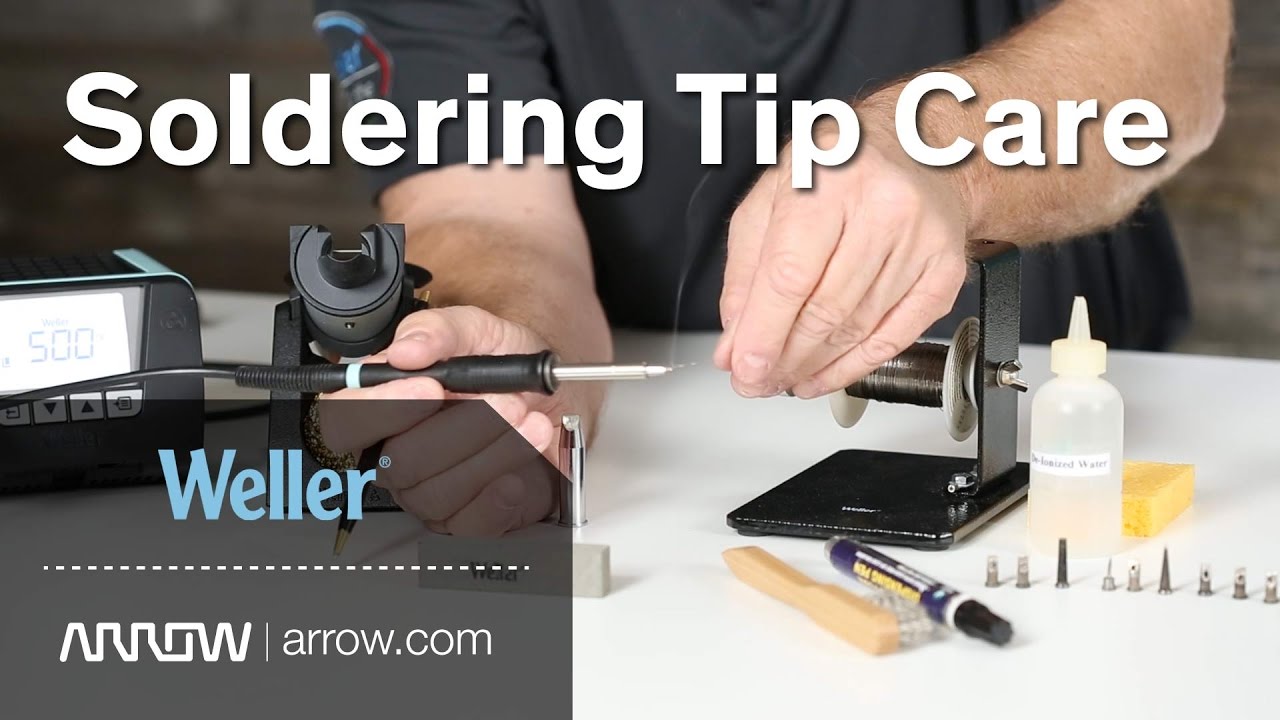

Once the whole tip is clean and shiny immediately add solder to it and it will flow smoothly around the whole tip.

How to make solder tips last longer. Do not hold the hairdryer still in an attempt to soften the solder. Put a nice little blob of solder on the tip of the iron. Will create a barrier between the metal and the solderThink of the dirty surface like plastic wrap over your ham sandwich your potential solder join.

As for your desoldering your going to have also replace the tips more. Cut it shorter than I. Use a small pair of pliers to help you get it tight.

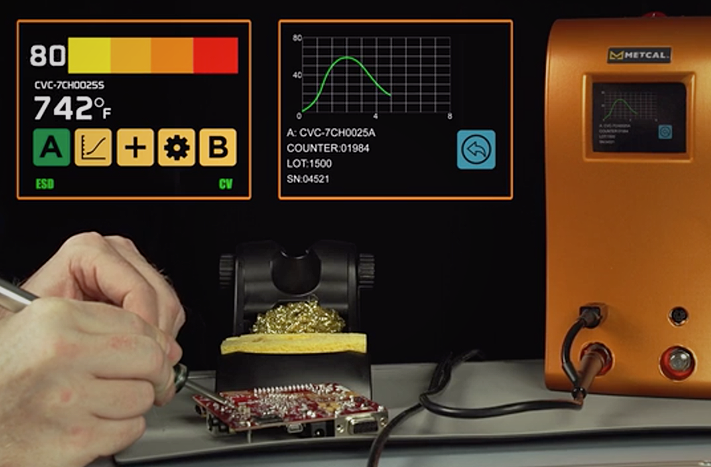

Touch the solder to the tip of the iron and make sure the solder flows evenly around the tip. Apply a small amount of solder paste to the join or area of metal that is going to be soldered. You should tin the tip of your iron before and after each soldering session to extend its life.

My interns come to me with this problem all the time. Try CND Stickey Base Coat 9. Use a hairdryer to warm to soldered joint.

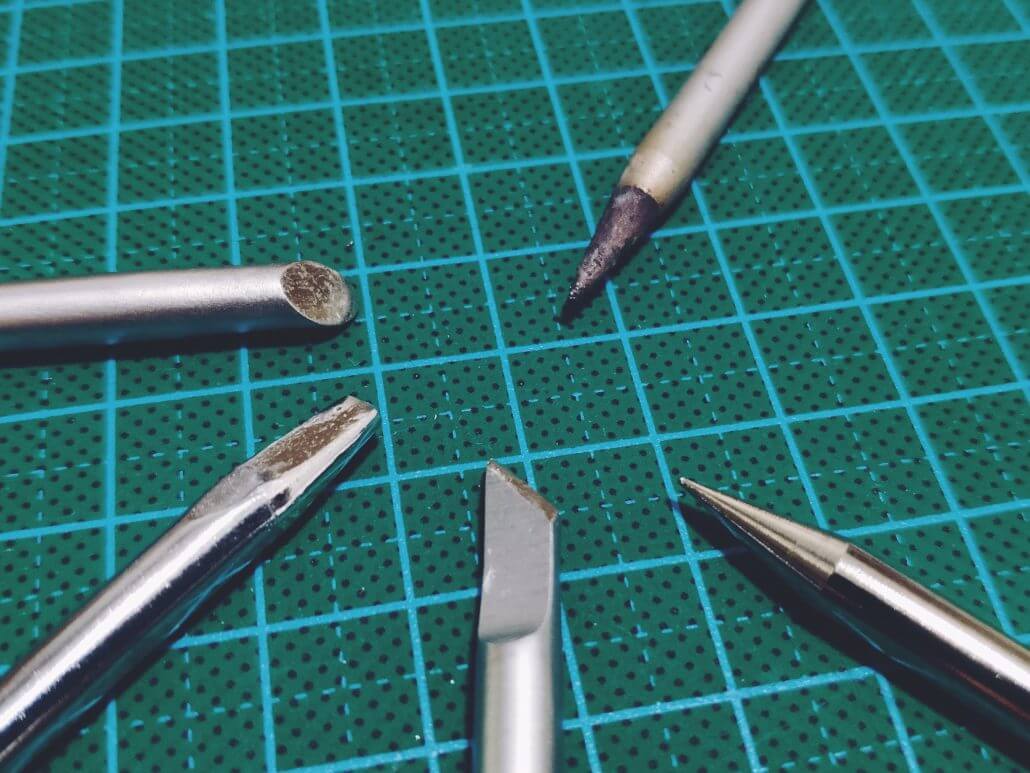

Simply get the solder warm. This prevented the copper from dissolving into the solder giving the tip a much longer and predictable operational life. Starting in the 1980s iron plating was added to the thermally efficient copper tip.

The next best might be a temperature controlled soldering iron that. So before starting the soldering clean the tip using a File or Sandpaper and make it glowing. Apply two coats of basecoat to the tips of your nails.