How To Improve Soldering Process

The basic principle is to make the amount of solder ball printed in the outermost row or four corners of the BGA more than that of the remaining solder balls.

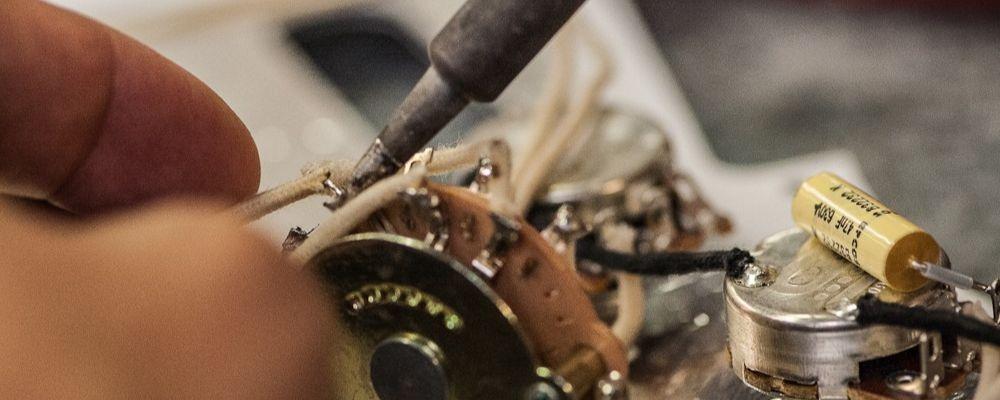

How to improve soldering process. To prevent burning your ngers use needle nose pliers heat resistant gloves or a third hand tool to hold small pieces. Increase board thickness or apply high TG material will enhance the board strength to give more robust to against stress. It is reflow and very easy compared to true soldering.

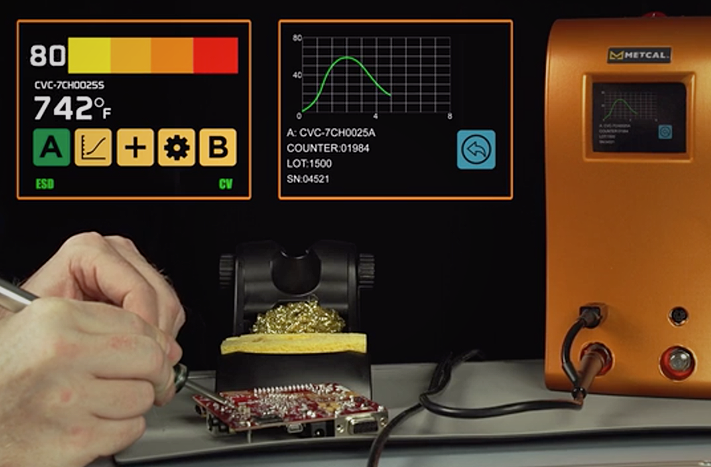

Thermal shocks occur when the temperature rises suddenly. The solder should flow in the opposite direction from that of the assembly. Preheating of PCBs is done using hot air heaters.

The solder metal has a lower melting temperature than the working piece. So before starting the soldering clean the tip using a File or Sandpaper and make it glowing. Here WorkingBear modify the stencil aperture size for BGA package to control the solder paste volume.

Soldering is the process that creates intermetallic bonds with metal surfaces that do not melt during application of the joining material solder. Since the soldering process is intermittent keep the soldering iron tip on a heat sink. Density component type.

This process helps to improve the heat transfer from the iron to the object to be soldered. In a drag process a stable solder flow is critical. Increasing the amount of solder paste locally rather than all of the solder ball pads increases the amount of solder.

Increasing time above liquidus will help to allow for the complete flow of the liquid solder before it begins to freeze. This process will help improve the heat transfer from the iron to the item youre soldering. Reflow soldering is the most widely used method of attaching surface mount components to printed circuit boards PCBs.