How To Improve My Tig Welding

Using an inverter power source is one of the first steps you can take to improve TIG welding efficiency.

How to improve my tig welding. 1 point 3 years ago. For the beginner it may be a very intimidating process. DC welding aluminum is no different.

TIG generates heat via an arc of electricity jumping from a tungsten metal electrode to the metal surfaces you intend to weld - usually aluminum. Invert the process. Like other kinds of welding TIG welding involves high heat and intense light.

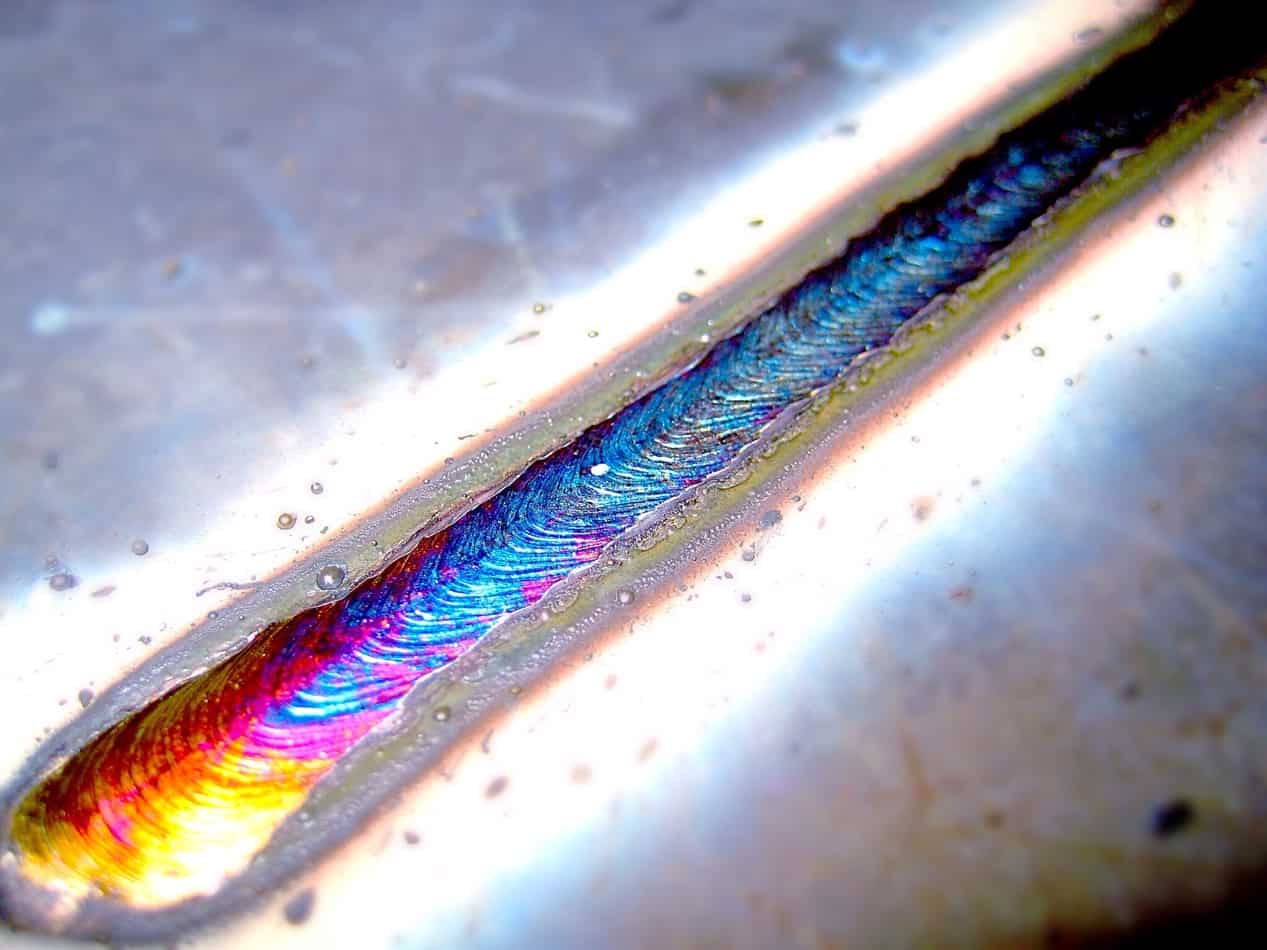

TIG welding in my opinion produces the best weld quality but that weld quality depends a lot on a clean joint. Often you can rest your wrists on the part being welded. Relatively new to Tig welding any advice on how to improve would be greatly appreciated.

Relatively new to Tig welding any advice on how to improve would be greatly appreciated. Hold the rod so it rests horizontally at approximately a 15-degree angle to the workpiece. Clean the scale off the metal before you weld it.

Current is related to the depth of penetration the welding speed and the quality of the weld. I found using them improves coverage. Use clean dry filler rod.

Sharing my go to method for TIG welding up a gap. Make sure your rod is clean and dry. Some welds work better with a point while others need a rounded tip.