How To Improve My Stick Welding

Based on the app.

How to improve my stick welding. A steady hand makes for a better weld and better lookingWhen taking a 6G test Id always stick my file or wire brush handle in the cupon or somthing. At this stage the only thing you can do is to break off the rod from the metal the tip of the electrode which includes the flux might fall off but you dont need to worry too much about it. A beginning stick welder can produce better welds by paying attention to the five basic elements to establish a good consistent technique.

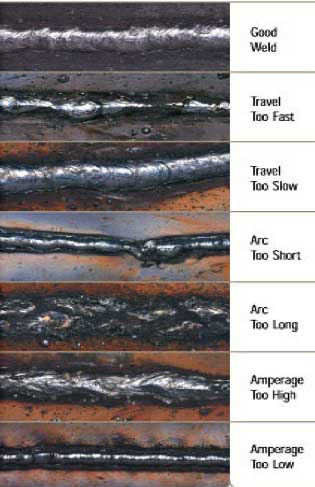

Although stick welding is more forgiving in these kind of situations this will save you from getting into unexpected troubles. I would start around 125 amps and make a test weld. With the correct current set on the welder machine you should get smooth neat welds with little or no splatter.

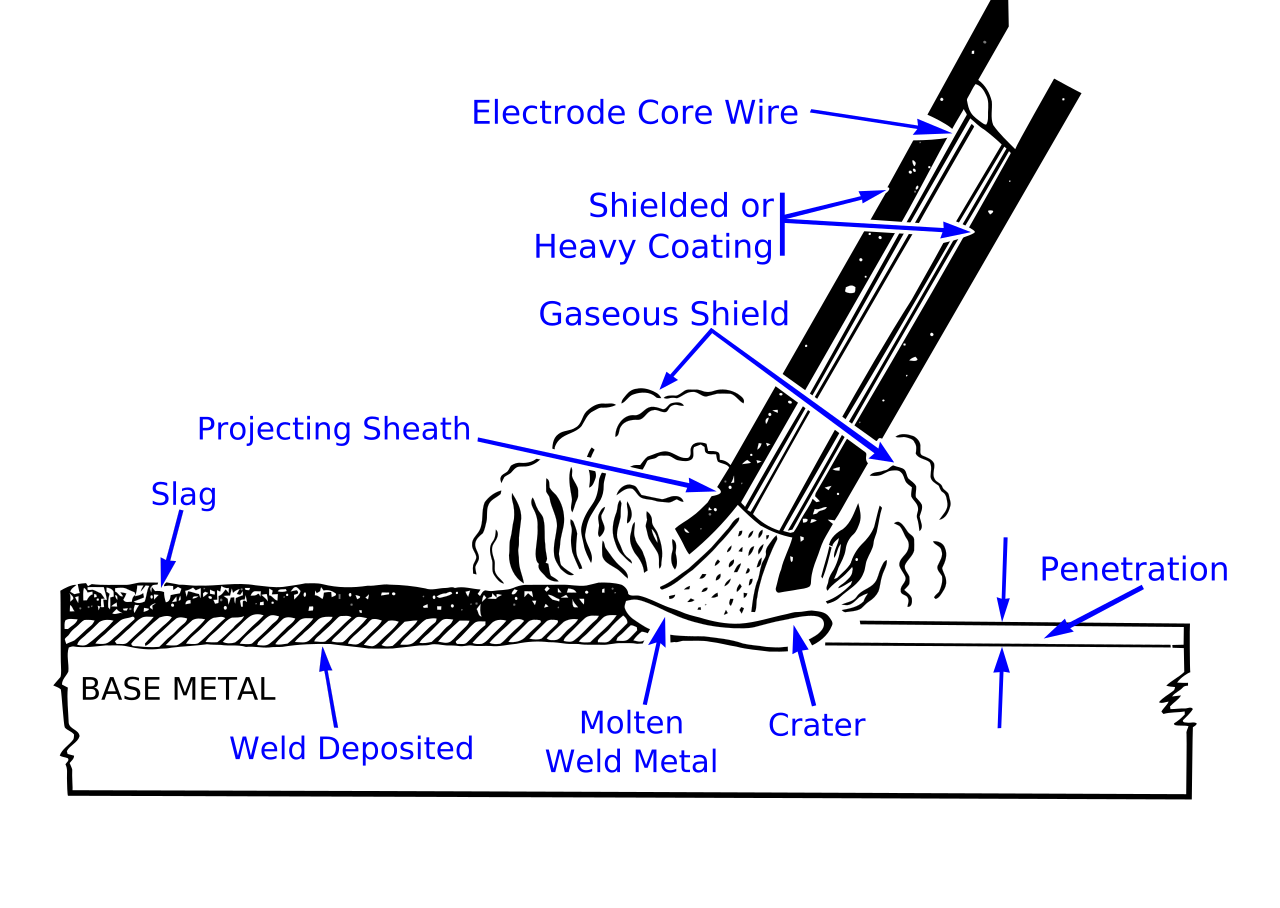

Current setting length of the arc angle of electrodemanipulation of electrode and speed of travel. Simply think about CLAMS. The DCEP polarity increases the weld bead width by increased globular metal transfer.

When you push you can see where you are going better but the puddle is blocked by the nozzle. If you need to make minute adjustments to the heat of the weld while under the hood during your stick weld the easiest way to achieve this is to pull the welding rod away from the weld puddle to long-arc slightly. Because DCEN concentrates a large proportion of heat in the base plate itself your HAZ area becomes wider.

Horizontal or 2G you point the rod upward between 30 and 45 degrees and drag it toward your direction of travel with a side tilt of 10 to 30 degrees. Vertical up or 3G point the rod up between 30 to 45 degrees. And if you cant find anything tack somthing up.

For more detailed information order a copy of Ne Le i Ac Weldig available from the James F. Skill comes only with practice. When you chose the DCEN polarity you will increase your weld penetration.