How To Fix Oxidized Solder Tip

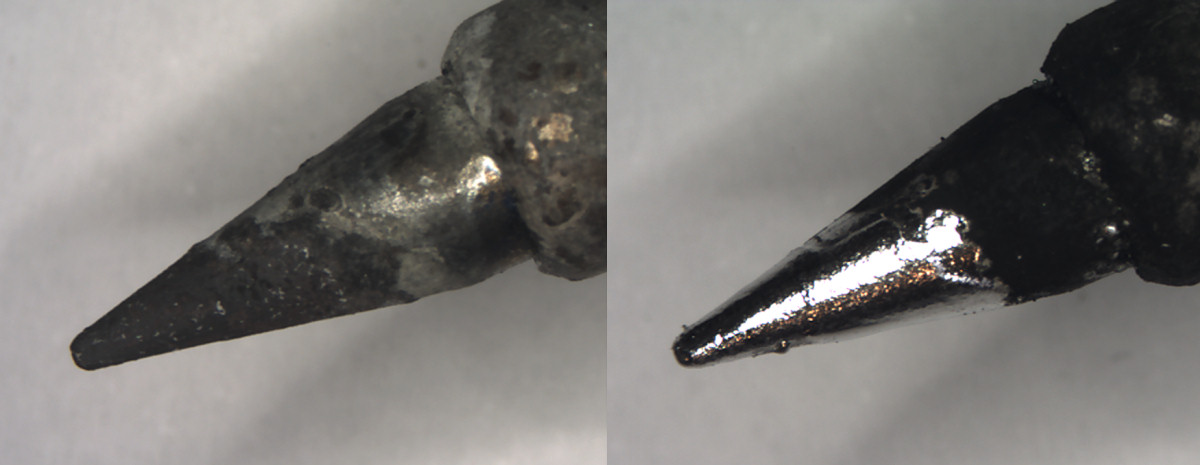

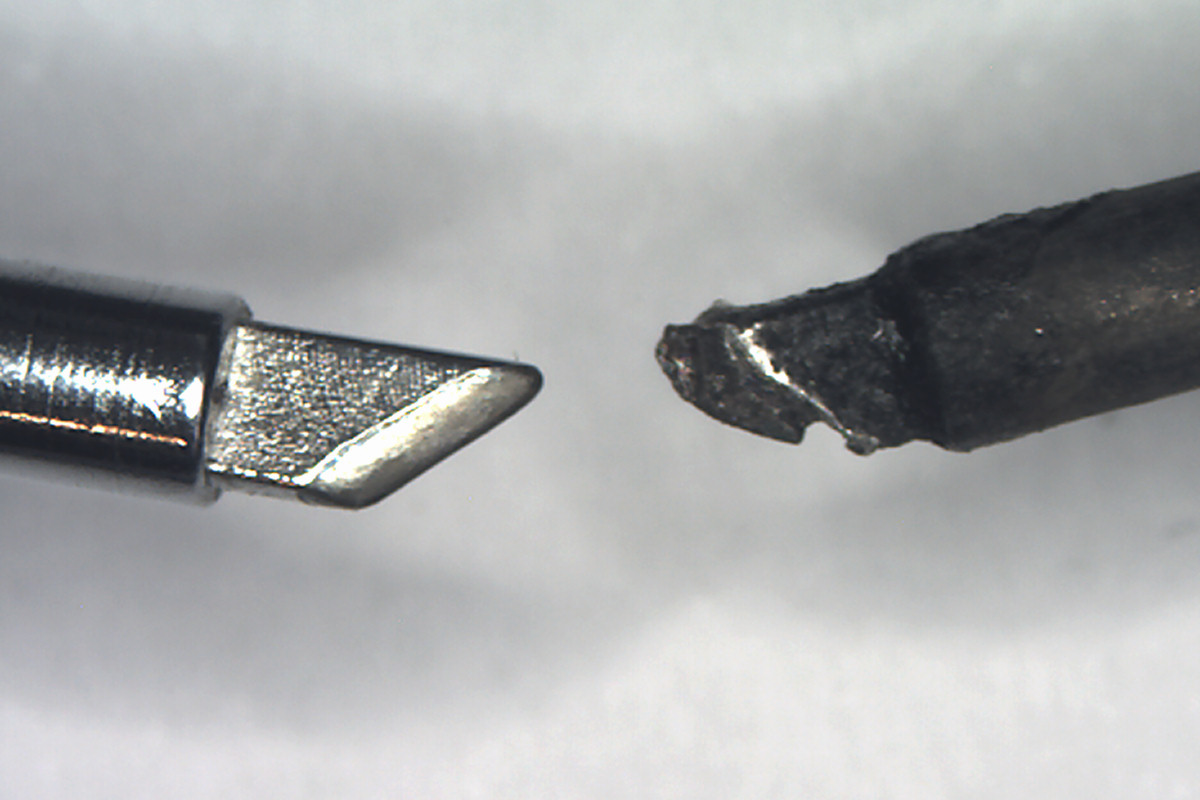

If some of the oxides are just sticking really well you could try to mildly abrade them on a brass sponge copper braid or similar but you cant be too hard or you will damage the iron plating good tips are typically copper core plated with iron then chromium everywhere but the working area.

How to fix oxidized solder tip. You can also use resin. How to adjust the temperature. If you are not going to solder for 3-5 minutes.

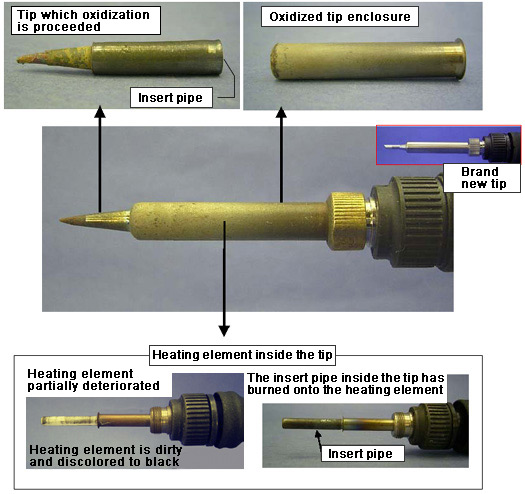

You can get pastes specifically designed to clean your soldering tips. In addition a heavy oxide can be formed on the pipe itself preventing a bond from forming between the filler metal and the pipe surface. How to use the temperature probe for the hot air rework system NoC1541 THERMOMETER SOLDERING TESTER.

Just like with sandpaper you must tin your soldering tip after cleaning to prevent prolonged oxygen exposure. How I overcame this problem - was to place a variac in series with the electric soldering iron. For that use resin-layered cardboard.

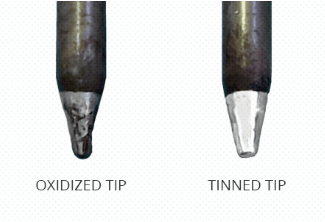

The tip gets black and solder is not sticking to it anymore. If your soldering tip becomes detinned oxidized it can be restored in a number of ways. Try not to leave the iron sitting hot on the bench while not in use.

Turn it off as soon as you have finished soldering. Maintenance and inspection of soldering pots. To clean the tip you need either stainless steel wool or good brass.

The best way is to prevent the soldering iron tip from oxidizing. Once the re-tinning product melts around the tip hold it for several seconds and then clean the tip using dry cleaning methods like brass wool or an automatic tip cleaner. The problem here I believe lies with the soldering-tip temperature.