How To Clean Flux Residue After Silver Soldering

Cleaning the flux residue.

How to clean flux residue after silver soldering. Flux removal is a simple but essential operation. But be careful Acetone is Flammable and is definately also not good to Breathe. I like to do this as it allows you to make a thorough inspection of the joint to ensure the solder has flowed completely around the circumference of the pipe and there is no pinholes.

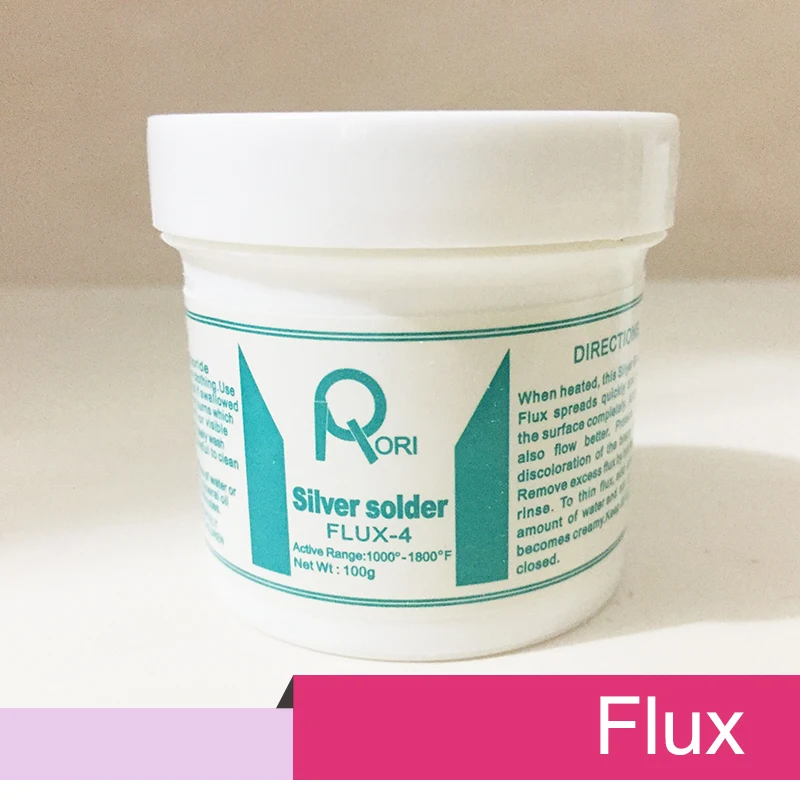

This Rosin flux will NOT be removed with water. Most of the acid core solder I have is not for potable water because it contains lead and acid. When I use flux such as for silver soldering brass or steel to copper I clean the completed joint with a long strip of rag which has been wet with hot water.

You can also remove these oxides by abrasion using files or abrasive paper but using a pickle is more efficient. With light heat and vacuum there will be no water residue and the part can then be cleaned with an alcohol based cleaner in the ultrasonic cleaner which flashes off just as well. Flux residues are chemically corrosive and if not removed could weaken certain joints.

The best way of removing this is to immediately plunge the item into boiling water while it is still hot from soldering. Intermediate and Corrosive Solder Fluxes Halides These fluxes leave a fused residue which absorbs airborne moisture causing a slow chemical reaction at the joint. One way to fix this problem is to lower the temperature when soldering.

Rosin flux works best where the surface to be soldered isnt too dirty or has too many impurities. Rosin mildly activated works best for the filthy surfaces and. After soldering we using Vapor Degreaser process with RHO-TRON 225 AES-L to clean up the flux.

Then take a wire brush to clear off the residues and smut. After soldering they prevent unconsumed activators from dissolving in water. Another option is the use of a vacuum to reduce boiling point of water.