Do Soldering Tips Wear Out

Heres what you can do to keep your soldering iron working for years to come and prevent badly maintained solder tips from affecting your work.

Do soldering tips wear out. Soldering iron tips wear out over time and unfortunately if your tool fails to transfer heat to the connection point effectively then it must be deemed unreliable and ultimately expendable. How do you know if a soldering tip is bad. Remember to keep tips always tinned even when you finish your job.

Soldering tips wear out over time and eventually need replacing but taking steps to care for your tips can extend their life save you money and improve the results of your soldering work. In addition to that soldering iron tip tends to wear out as time progresses and will eventually require a replacement. However by taking good care of your soldering iron tip you will be able to boost its longevity significantly hence saving your money and improving your soldering skills.

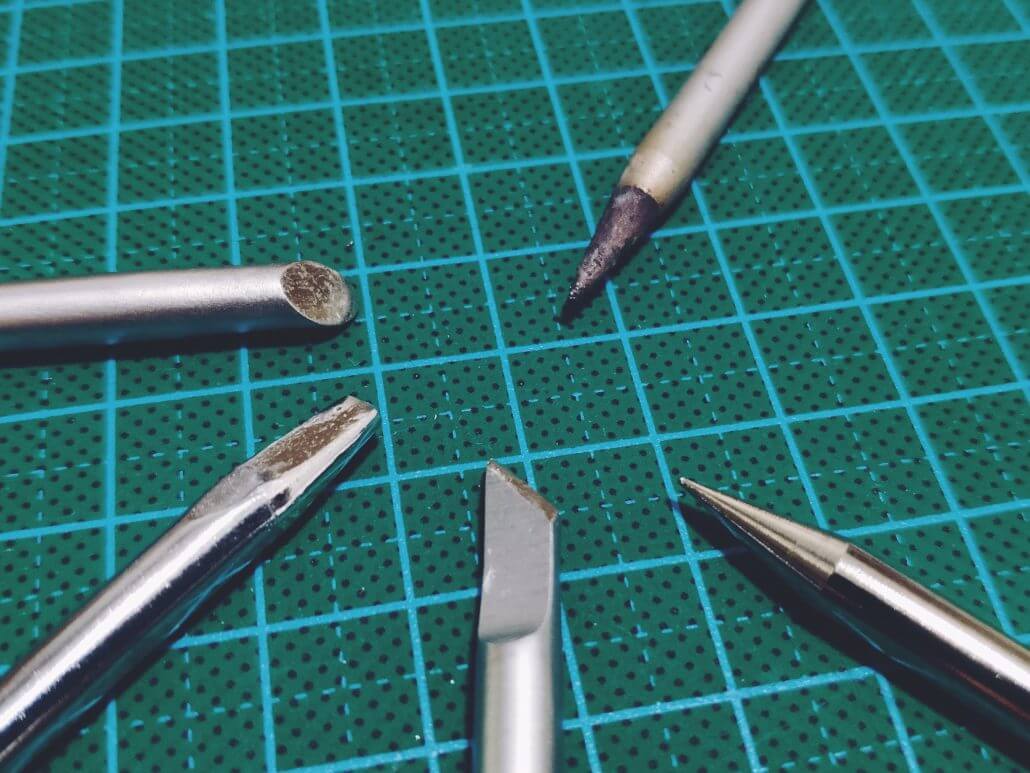

Eventually every tip will wear out and will need replacing when it becomes rough or pitted. All tips eventually wear out due to heat and normal use. A hollow forming in the end of the tip cleaning and re-tinning has no effect or needs frequent repeating.

NEVER file a soldering tip. I think that this happens because I use a cheap tip and I sometimes lay big blobs of solder on the tip for a while until I finish some connections. And the hotter the iron the faster this erosion occurs.

Corrosion from the tin content in the solder as it reacts with iron which is the. Abrasion from rubbing the tip against pads RF shields component terminations or pressing against trimmed leads. Protecting your solder tips can start as early as from the beginning of a solder tips lifetime.

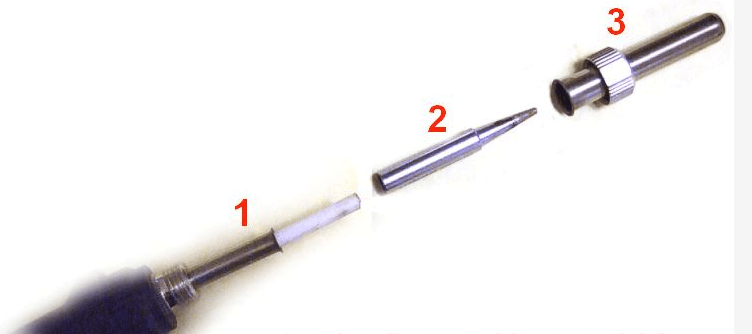

Yes I use the a cleaning wire the one for the dishes since the wet sponge cools the tip and corrodes it faster. On tips with heating elements built into the tips themselves IE. Tip plating failures for all solder tips can be divided into four main classes.